News & articles

The quality of the PCB assembly process could have a positive or an inimical impact on how well health care providers will be able to cleanly integrate flexible sensors into their operations.

How can manufacturers tell the difference between the good PCB assemblers that will enhance their processes and the bad ones that will wreak havoc on their productivity?

What’s missing from your unbelievably inexpensive box build?

Electronics makers working to align their technology with the military’s vision of tomorrow will notice an increased need for high-quality printed circuit board and system assembly capabilities.

How will PCBs and PCBA direct the business leaders of tomorrow as they attempt to predict where this new age of production will take us?

Let’s walk through the three major steps in the PCB inspection process and demonstrate their value, as well as ways PCB assemblers accelerate the process without detracting from its integrity.

Is the U.S. the best location for PCB assembly?

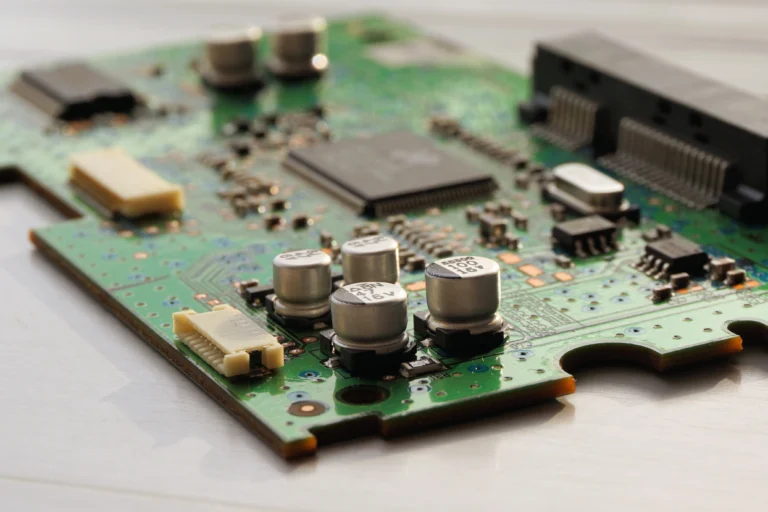

As electronics continue to shrink in size, PCB assembly faces new challenges and must meet a higher standard of expertise to continue servicing the most innovative electronics providers.

What is the current status of electronics and PCB component counterfeiting today, why does it matter and how can you and your business avoid falling victim?

Surface-mount technology has been around since the 1980s as a lead design blueprint for PCBA—but will its past dictate the future?

Every industry has its tips and tricks to reduce costs and make certain processes a little more cost-efficient, and PCBA is no stranger to this.

The Internet of Things is generating a lot of traction in a number of industries, but printed circuit board assembly could stand to gain the most.

The military and defense contractors are now more technologically advanced than ever, and the success of the industry is translating into big paydays in the future for printed circuit board manufacturers.

Athletics have entered the digital age and PCBA is playing a large role in facilitating that transition.

A recent discovery in Tanzania could provide a sharp boost in production for the medical sector of PCBA manufacturing.

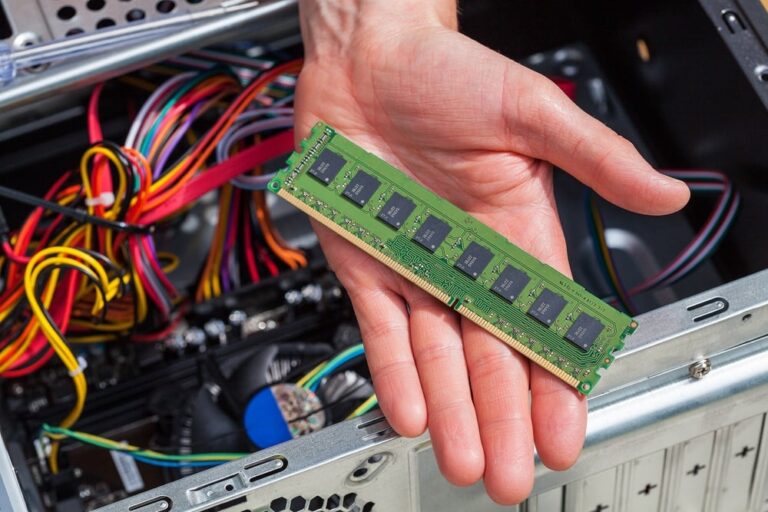

It’s an undeniable fact that the printed circuit board manufacturing industry has changed incredibly over the last decade alone. Extend this to 20 or 30 years, when personal computers were first hitting the shelves, and the advancements are truly astonishing.

Behind every device is a manufacturing team who created it.

The printed circuit board industry experienced excellent year-over-year growth recently.

Printed circuit boards may be the driving force at the heart of nearly every product we use today, but it wasn’t always like that.

New technology is requiring PCB manufacturers to miniaturize components to fit unique specifications, which means breaking the conventional rules day after day.

The growth of technology doesn’t stop for anybody, which is why it’s incredibly important to stay ahead of trends when it comes to manufacturing parts for devices.

If you know the biggest mistakes, you’ll be able to spot flaws in manufacturers’ practices and identify the truly excellent partners.

You must be prepared to learn everything you can about potential manufacturer partners before signing on that dotted line.

Don’t forget these aspects of PCB design prototyping!

The performance of PCBs matters more than ever for military organizations.

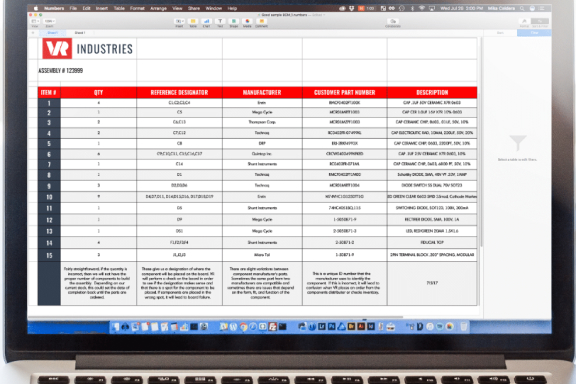

To help your partners realize your vision, we’ve put together the five laws of PCB documentation.

Here’s how to to make sure your manufacturing partner is on track with the optimal processes for PCB assembly and surface mounting.

Let’s check out some of the ways in which your PCB manufacturing partners can improve their sustainability profiles.

Let’s take a closer look at PCB markets and highlight a few of the factors driving this segment forward.

Let’s look at 5 elements of the ideal PCB manufacturing and assembly partnerships.