Design for Testing Services

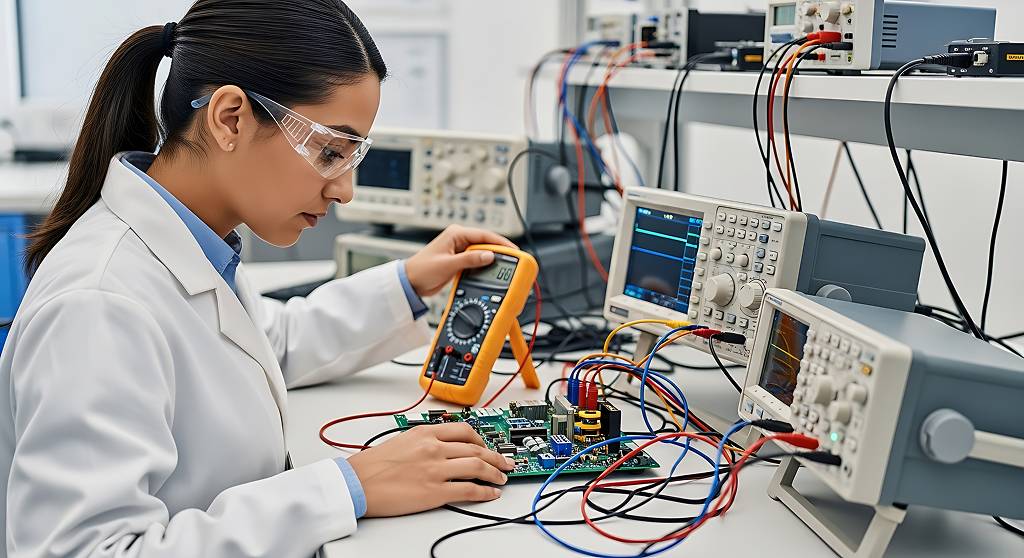

Maximizing Testability Through Collaborative Engineering

Our DFT services address potential testing challenges early in the design phase, preventing costly modifications and delays during production. By partnering with VR Industries, you gain access to decades of manufacturing expertise that translates into more reliable, cost-effective products.

What is Design for Testing?

Design for Testing involves implementing specific features and methodologies into your product design to facilitate effective testing during manufacturing. This proactive approach identifies and resolves potential issues before production, significantly reducing costs and improving quality. Proper DFT implementation ensures that your electronic assemblies can be thoroughly evaluated using automated testing equipment, resulting in higher reliability and customer satisfaction.

Our DFT Capabilities

Strategic Test Point Placement

We review your PCB layout to ensure test points are accessible for automated optical inspection (AOI), in-circuit testing (ICT), and functional testing. Our engineering team identifies optimal locations for test points that maximize test coverage without compromising design integrity or increasing board size unnecessarily.

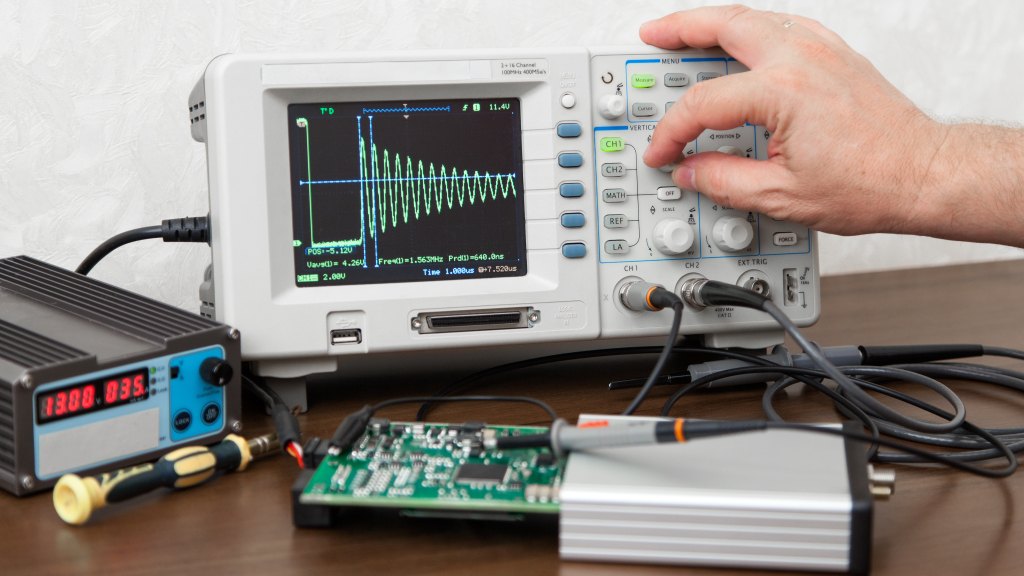

Improved Fault Isolation

DFT integration allows for faster troubleshooting and failure analysis—cutting debug time and field returns. By implementing proper test access points and boundary scan techniques, we enable precise identification of manufacturing defects, component failures, and design issues, reducing the time and cost associated with repairs.

Test Coverage Optimization

Our team helps you strike the right balance between test thoroughness and cost, ensuring high reliability without overengineering. We analyze your product's critical functions and failure modes to develop a targeted testing strategy that provides comprehensive coverage where it matters most, optimizing both quality and manufacturing efficiency.

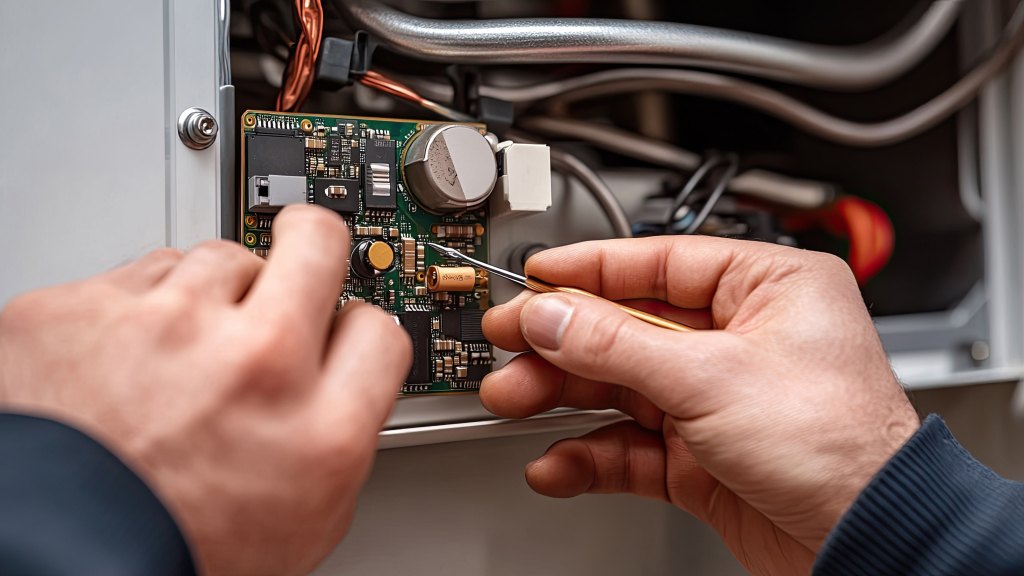

Built-in Diagnostics and Interface Access

We advise on integrating onboard diagnostics, headers, and communication protocols to support production and field testing. These features enable efficient verification of product functionality during manufacturing and simplify troubleshooting throughout the product lifecycle, reducing support costs and improving customer experience.

Higher Yields and Fewer Escapes

A strong DFT approach increases first-pass yields and minimizes the risk of undetected defects reaching your end users. By implementing robust testability features, we help ensure that potential issues are identified and resolved during manufacturing, protecting your brand reputation and reducing warranty costs.

The VR Industries DFT Advantage

Our Customer Innovation Center (CIC) provides a collaborative environment where your team can work directly with our manufacturing experts to optimize product testability. This partnership approach ensures that DFT considerations are integrated seamlessly into your design process, resulting in:

Reduced time-to-market through fewer design iterations

Lower manufacturing costs through improved process efficiency

Enhanced product quality through comprehensive testing

Increased customer satisfaction through improved reliability

Partner with VR Industries for DFT Excellence

With decades of manufacturing experience across medical, defense, and industrial sectors, VR Industries understands the critical importance of thorough testing in high-reliability applications. Our DFT expertise enables you to focus on innovation while we ensure your products can be efficiently validated during manufacturing.

Contact VR Industries today to learn how our Design for Testing services can enhance the quality, reliability, and manufacturability of your electronic products.