Collaborate

Collaborate with VR Industries

At VR Industries, collaboration represents the foundation of our manufacturing philosophy and the cornerstone of our customer relationships. We believe that true contract manufacturing collaboration goes beyond transactional manufacturing services to encompass strategic partnership that enhances product development, optimizes manufacturing processes, and accelerates time-to-market for innovative electronic solutions.

The Power of Strategic Manufacturing Partnerships

Contract manufacturing partnership with VR Industries means gaining access to a dedicated team of professionals who understand your business objectives and work proactively to support your success. We invest in understanding your products, markets, and challenges, enabling us to provide insights and recommendations that drive continuous improvement and innovation.

Ask an Expert

Manufacturing Collaboration Benefits

Enhanced Product Development:

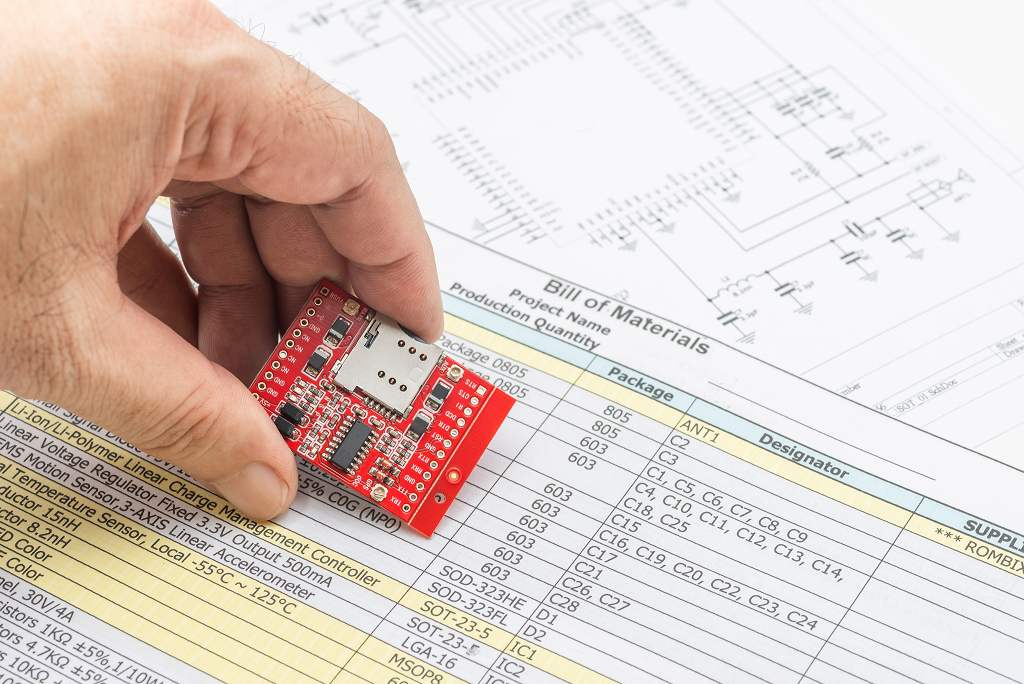

Design for Manufacturing (DFM) optimization that improves manufacturability and reduces costs

Access to manufacturing expertise during product design phases

Rapid prototyping capabilities that accelerate development cycles

Engineering support for component selection and process optimization

Operational Excellence:

Scalable manufacturing capacity that adapts to demand fluctuations

Advanced quality control systems that ensure consistent performance

Supply chain expertise that mitigates risks and optimizes costs

Comprehensive testing and validation capabilities

Strategic Advantages:

Focus on core competencies while leveraging manufacturing expertise

Reduced capital investment requirements for manufacturing equipment

Access to specialized certifications and regulatory compliance expertise

Flexibility to respond rapidly to market opportunities and changes

Customer Innovation Center Excellence

Our Customer Innovation Center (CIC) exemplifies our commitment to collaborative product development by providing a dedicated space where your team can work directly with our manufacturing specialists to optimize designs, validate processes, and accelerate product development. The CIC enables hands-on collaboration that transforms concepts into manufacturable products.

Through the CIC, we facilitate iterative design optimization, process validation, and manufacturing readiness assessment that ensures smooth transitions from development to production. This collaborative environment reduces development risks while accelerating time-to-market for innovative electronic solutions.

The CIC experience includes access to our engineering expertise, manufacturing knowledge, and specialized equipment that enables comprehensive product development support. We work alongside your team to address challenges, optimize solutions, and implement best practices that enhance manufacturing outcomes.

Dedicated Program Management

Our dedicated Program Management approach ensures that every collaboration receives focused attention and proactive support throughout the entire project lifecycle. Each customer is assigned an experienced Program Manager who serves as a single point of contact for all manufacturing-related activities and communications.

Program Managers coordinate cross-functional teams, manage project timelines, and provide regular updates that keep all stakeholders informed and aligned. This personalized approach enables responsive communication, rapid issue resolution, and proactive problem prevention that supports successful project outcomes.

Our Program Management philosophy emphasizes partnership over transactions, focusing on long-term relationships and mutual success rather than short-term project completion. We invest in understanding your business objectives and work continuously to optimize our support and services.

Technical Expertise and Consulting

We stay current with emerging technologies, industry trends, and regulatory requirements that impact electronics manufacturing, enabling us to provide forward-thinking recommendations and solutions that anticipate future needs and market changes.

Supply Chain Partnership

Our supply chain partnership extends beyond component procurement to include inventory management, obsolescence planning, and alternative sourcing strategies that ensure long-term product availability and cost stability.

Quality Partnership Approach

We maintain ISO 9001 and ISO 13485 certifications while adapting our quality systems to meet customer-specific requirements and industry standards. Our quality partnership ensures that products meet or exceed specifications while maintaining the efficiency required for competitive manufacturing.

Innovation and Technology Partnership

Our technology partnership includes ongoing capability assessment, roadmap planning, and implementation support that ensures our manufacturing services evolve with customer needs and market requirements.

Regulatory Compliance Collaboration

Our collaborative approach to regulatory compliance includes joint planning, documentation development, and audit support that ensures successful regulatory submissions and ongoing compliance maintenance.

Long-Term Partnership Value

We measure our success by customer success, focusing on metrics that matter most to our collaborative partners including quality performance, delivery reliability, cost competitiveness, and innovation support.

Getting Started with Collaboration

We provide transparent communication about our capabilities, processes, and expectations while working to understand your requirements and preferences. This mutual understanding forms the foundation for successful long-term collaboration.