Life Sciences Contract Manufacturing

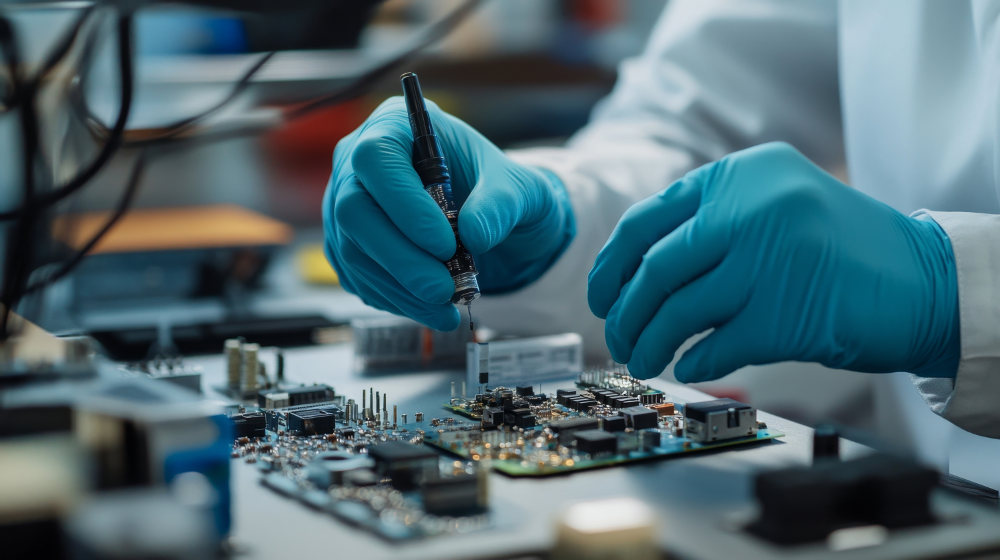

Advancing Life Sciences Innovation Through Precision Manufacturing

VR Industries provides comprehensive life sciences contract manufacturing solutions, focusing on the critical electronic components that power today’s advanced diagnostic, analytical, and therapeutic devices. With our legacy of manufacturing excellence dating back to 1985, we support life sciences innovators through every stage of the product lifecycle from initial design collaboration to full-scale production. Our commitment to quality, reliability, and regulatory compliance ensures seamless manufacturing processes, empowering our clients to focus on their core mission: advancing life sciences technology.

Supporting Breakthrough Innovations

In the field of laboratory diagnostics, we manufacture precision-engineered control systems for analytical instruments. These systems enable accurate test results and reliable performance for devices that healthcare providers depend on for patient diagnosis and treatment decisions. Our manufacturing processes maintain the highest standards of quality to support the sensitive nature of diagnostic equipment.

ISO 13485 Compliance for Medical Devices

Quality isn’t just a priority for us it’s built into our processes. Our ISO 13485 certification underscores our commitment to continuous improvement and excellence in medical device manufacturing. This robust quality management system provides our life sciences customers with:

- Documented design control processes

- Comprehensive risk management

- Validated manufacturing processes

- Consistent quality assurance

- Rigorous material control systems

Miniaturization & High-Density PCB Assembly

The trend toward smaller, more powerful life sciences instruments demands advanced manufacturing capabilities. Our state-of-the-art Surface Mount Technology (SMT) lines and specialized assembly processes support:

High-component-density designs

Fine-pitch component placement

Advanced microelectronics assembly

3D component stacking

Complex multi-layer boards

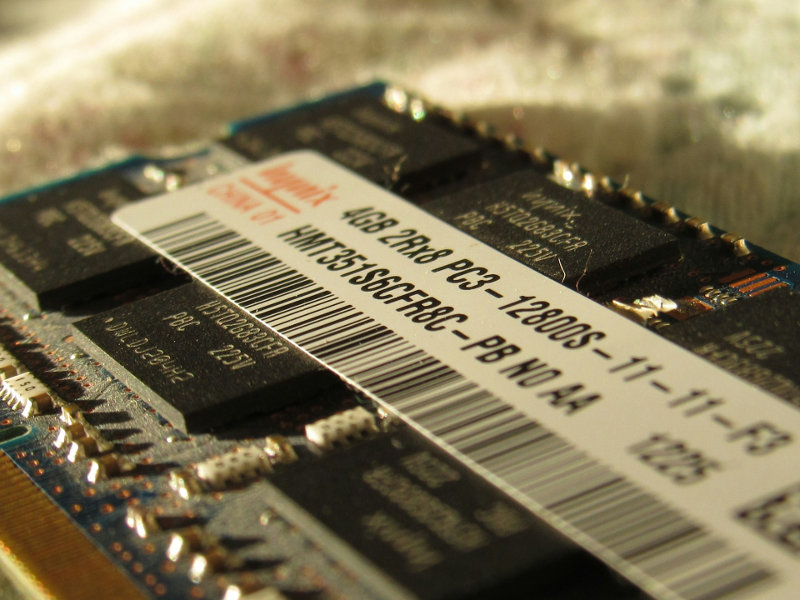

Traceability & Serialization

Process documentation is meticulously maintained throughout production, capturing critical parameters and verification steps that ensure consistent quality. Our revision control systems ensure that all manufacturing is performed to the correct specifications, with clear documentation of any design or process changes that occur over the product lifecycle.

End-to-End Manufacturing Support

Design for Manufacturability (DFM)

Early collaboration to optimize designs for efficient production

New Product Introduction (NPI)

Structured processes to transition from prototype to production

Supply Chain Management

Strategic sourcing and inventory management to ensure material availability

Testing and Validation

Comprehensive testing protocols to verify performance

Final Assembly and Integration

Complete system assembly and functional verification

Manufacturing Excellence for Life Sciences

Our manufacturing facility is equipped with advanced capabilities specifically designed for mission-critical life sciences applications:

Precision Manufacturing Systems:

Advanced electronic assembly capabilities

Comprehensive testing protocols

Specialized integration facilities

Quality Assurance:

ISO 9001 and ISO 13485 certified processes

FDA registered manufacturing facility

Multi-stage inspection systems

Complete traceability protocols

Technical Expertise:

High-tolerance assembly capabilities

Rigorous process controls

Advanced failure prevention systems